News & Events

-

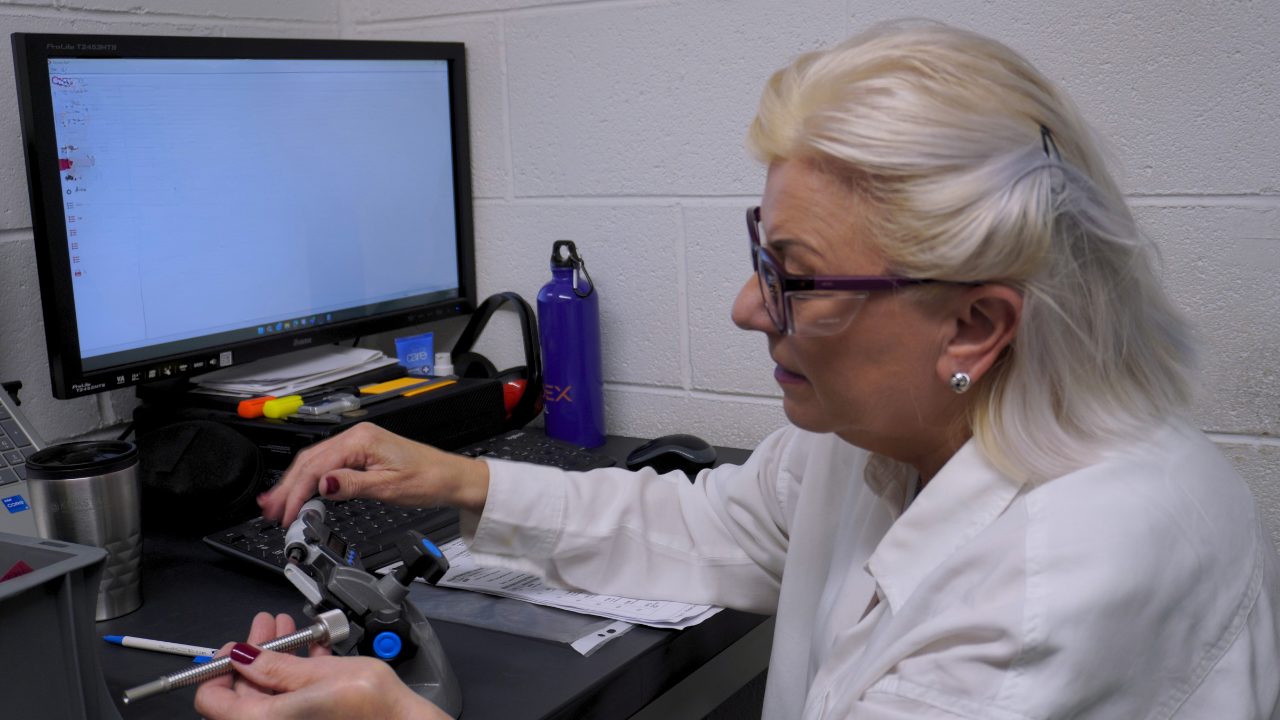

How Clare Firth keeps quality at the heart of Kirkstall Precision

Read more: How Clare Firth keeps quality at the heart of Kirkstall Precision -

What we’ve learned from CES 2026 and why it matters for MedTech Manufacturing

Read more: What we’ve learned from CES 2026 and why it matters for MedTech Manufacturing -

How apprenticeships are shaping the future of med-tech manufacturing

Read more: How apprenticeships are shaping the future of med-tech manufacturing -

Chris Remmer on how experience and craft shape life-changing instruments

Read more: Chris Remmer on how experience and craft shape life-changing instruments -

How Sarah Wood is reshaping operational excellence at Kirkstall Precision

Read more: How Sarah Wood is reshaping operational excellence at Kirkstall Precision -

Shaping the future of Kirkstall Precision: A conversation with Craig Dowling

Read more: Shaping the future of Kirkstall Precision: A conversation with Craig Dowling -

Why UK-based manufacturing matters in med-tech

Read more: Why UK-based manufacturing matters in med-tech -

A closer look at the Dual Hinge Inserter Alignment Tool

Read more: A closer look at the Dual Hinge Inserter Alignment Tool -

A conversation with Lucyna Kubik on precision, care, and quality

Read more: A conversation with Lucyna Kubik on precision, care, and quality